Dakota del Norte, EE.UU.

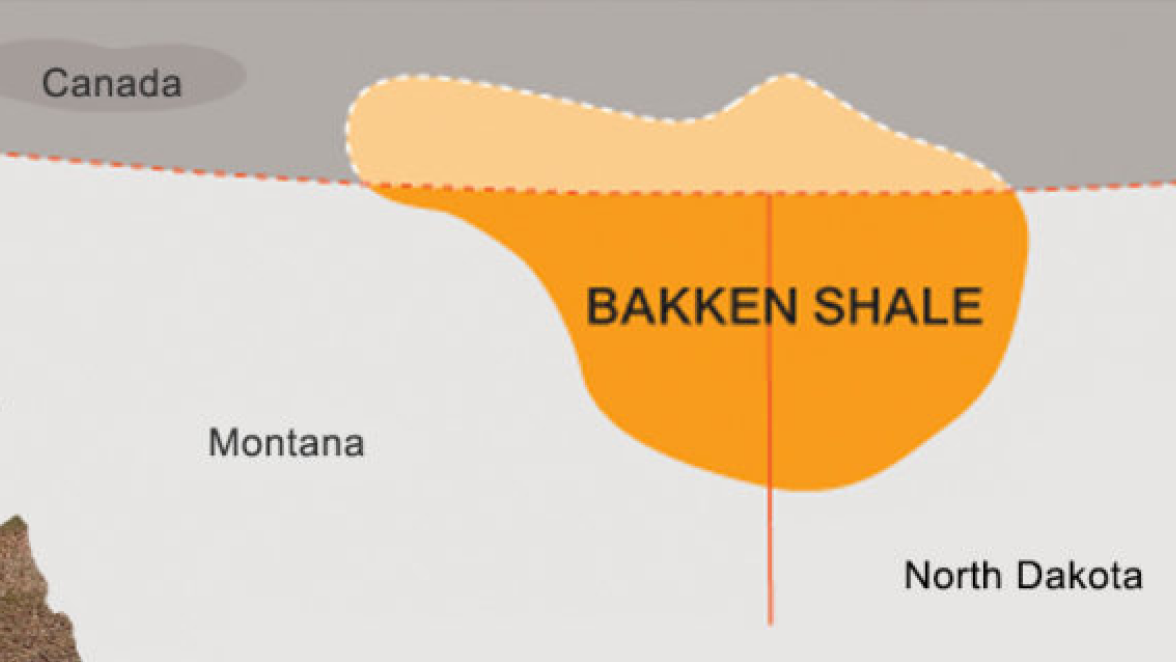

Distributed LNG Production: Galileo’s flare reduction solution for Bakken

Galileo Technologies, in partnership with SPATCO Energy Solutions, commissioned an innovative solution for Terra Energy in North Dakota’s Bakken shale region to integrate flare gas capture and liquefied natural gas (LNG) production right at the wellhead.

The core of this solution, engineered at Galileo Technologies’ headquarters in Buenos Aires, Argentina, includes a ZPTS® Plant for Gas Conditioning and a Cryobox® LNG-Production Station, which turns natural gas into 7,800 to 8,500 gallons of LNG per day based on production output from the wells.

The equipment is fully modular, electric driven and reliable when operating under the harsh conditions of North Dakota’s oil fields, which are home to frigid winters and scorching summers

Thanks to this innovative design, the LNG produced is stored on-site while the boil-off gas is recovered and re-liquefied. LNG is then transported and consumed for drill-rig power generation and frac-water heating.

Bakken shale region.

LNG is obtained through the gas from a well pad owned and operated by one of the largest producers and holders of natural gas reserves in the US, located less than 50 miles (80 km) from the sites where LNG is consumed.

“This is a complete solution,” said Dustin Hancock, President of Terra Energy Group. “We turned the flaring problem into an opportunity. The technology supplied by Galileo allows us to significantly reduce the waste of flaring using that energy to produce additional oil and gas.”

Distributed LNG-Production: LNG from scattered wells

“The abundance of shale and tight gas in certain regions, such as Bakken in the US or Vaca Muerta in Argentina, increases the relevance of natural gas as a source of clean energy. However, the dispersion of shale gas sources in these isolated areas can make the laying of gas-gathering lines economically unsustainable and creates an environmental problem”, explained Osvaldo Del Campo, Galileo Technologies CEO.

“In recent years and due to this barrier, more than 25% of the natural gas produced in North Dakota has been flared rather than sold to customers or consumed on-site. We believe that more of the unconventional gas can be monetized through methods such as the Distributed LNG Production solution we developed for Terra Energy,” added Del Campo.

“When long distances are involved, our ultra-compact gas conditioning and liquefaction modules allow us to distribute clean natural gas, affordably and without pipelines. This technology facilitates the collection of fuel from scattered sources and its distribution to consumers, applying road distribution logistics similar to those of other liquid fuels”, he concluded.

“This technology facilitates the collection of fuel from scattered sources and its distribution to consumers, applying road distribution logistics similar to those of other liquid fuels".

Osvaldo del Campo - CEO of Galileo Technologies

"In cases of long distances, our ultra-compact gas conditioning and liquefaction modules allow us to distribute clean natural gas affordably and without pipelines. This technology facilitates the collection of fuel from scattered sources and its subsequent distribution among consumers, through logistics similar to that employed with other liquid fuels," concluded.

A profitable solution to the flaring problem

“As gas capture requirements continue to ramp up, expecting to reach 90% by 2020, Galileo’s liquefaction technology will give the upstream oil & gas sector a means to master their challenges with profitability,” remarked Jeff Dailey, President and CEO of SPATCO Energy Solutions.

“The industry is experienced in the use of compressed natural gas (CNG) to reduce flaring, so LNG represents the advantage of cheaper distribution, beyond 100 miles (150 km). LNG just makes more sense if we consider that the industry needs to fuel high horsepower applications at remote locations, such as rigs, frack crews, heavy duty trucking and railways”, Dailey added.

Cryobox LNG Production Station conected to LNG tanker.

ZPTS Plant for Gas Conditioning connected to the Cryobox.